In today’s competitive manufacturing industry, precision, speed, and efficiency are the cornerstones of success. For small businesses and startups, investing in the right CNC Milling Machine can be the key to scaling production without compromising on quality. Unlike traditional manual milling methods, CNC (Computer Numerical Control) technology allows businesses to produce highly accurate and repeatable parts, even in low-volume settings. This makes CNC milling machines a game-changer for startups that aim to compete with larger manufacturers.

But how do you choose the best CNC milling machine for a small business? In this guide, we’ll explore the benefits, features to consider, and the top reasons why investing in a reliable CNC machine can boost your startup’s growth.

Why CNC Milling Machines are Essential for Startups:

Small businesses often face two big challenges: limited resources and the need for high-quality output. CNC milling machines address both issues effectively:

- Precision and Accuracy

CNC milling machines are designed to create exact replicas of a design, ensuring that every piece meets strict tolerances. This is particularly beneficial for startups that cannot afford production errors or wasted materials. - Efficiency and Speed

Manual operations are time-consuming and prone to human error. CNC technology automates the cutting process, completing tasks in a fraction of the time, enabling businesses to fulfill client orders faster. - Cost Savings in the Long Run

While the initial investment may seem high, CNC machines reduce material waste and require fewer operators. Over time, this translates into significant cost savings for small businesses. - Flexibility in Production

Startups often need to produce small batches or custom parts for different clients. A CNC milling machine can handle various materials and complex designs without major retooling, giving you unmatched versatility.

Key Features to Consider When Buying a CNC Milling Machine :

When selecting the best CNC milling machine for your startup, there are several critical factors to evaluate:

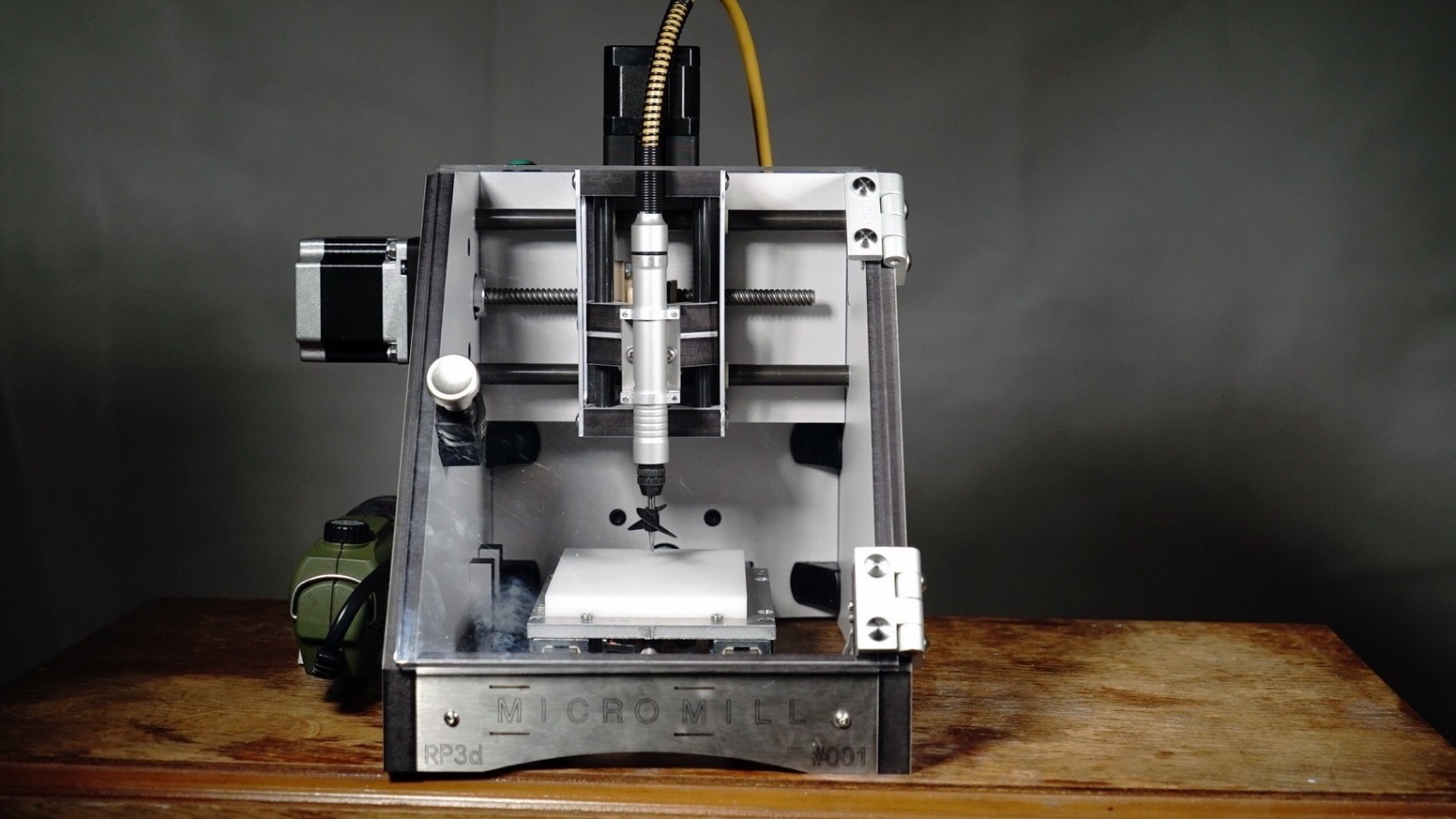

- Size and Footprint

Small businesses typically have limited floor space. Look for a machine that offers the right balance between compact size and production capacity. - Spindle Speed and Power

The spindle is the heart of the machine. Higher speeds and power ratings allow for faster material removal and smoother finishes, especially when working with metals. - Software Compatibility

Your CNC machine must integrate seamlessly with CAD/CAM software to translate designs into precise tool paths. This ensures that complex parts can be manufactured without errors. - Ease of Use

Startups may not have experienced machinists on staff. User-friendly interfaces, automatic tool changers, and guided programming features can reduce the learning curve significantly. - Maintenance and Support

Reliable after-sales service and the availability of spare parts are crucial. Downtime can be costly for small operations, so choose a manufacturer known for dependable customer support.

Benefits of Choosing a Trusted CNC Brand:

Not all CNC machines are created equal. Investing in a high-quality machine from a reliable brand like BORUI CNC ensures that you receive advanced features, precision engineering, and robust durability. Trusted brands often provide:

- Longer Machine Lifespan due to superior build quality.

- Better Accuracy for both small and large-scale projects.

- Reliable Technical Support to minimize downtime.

This kind of reliability is essential for startups where every project deadline and material cost matters.

How CNC Milling Machines Empower Small Businesses:

The integration of CNC milling machines can completely transform a small manufacturing setup. Here’s how:

- Increased Productivity: Automation allows you to handle multiple projects simultaneously without overloading your staff.

- Higher Profit Margins: Reduced labor costs and material waste lead to better profitability.

- Expanded Service Offerings: With a CNC machine, you can take on more complex orders and even explore new industries like automotive, aerospace, or custom prototyping.

- Professional Market Presence: Offering precision parts and faster turnarounds builds your reputation and credibility with larger clients.

Tips for Maximizing CNC Milling Machine ROI:

- Train Your Staff Properly

Even though CNC machines automate most tasks, skilled operators are still crucial for programming, setup, and maintenance. - Regular Maintenance

Follow the manufacturer’s maintenance schedule to ensure long-term machine performance and avoid unexpected breakdowns. - Start Small, Scale Gradually

Begin with the essential attachments and gradually upgrade as your production needs grow. - Use Quality Materials and Tools

The right tooling and raw materials enhance the accuracy of your parts and prolong machine life.

Conclusion:

For small businesses and startups looking to compete in modern manufacturing, investing in the best CNC milling machine is a strategic decision. It not only enhances precision and efficiency but also opens the door to new business opportunities. By choosing a reliable machine from a trusted brand, training your staff, and following proper maintenance practices, you can ensure that your investment delivers long-term benefits.

A CNC milling machine is more than just equipment—it’s a growth engine for your small business. If you’re ready to elevate your production capabilities, start exploring high-quality models that align with your space, budget, and manufacturing goals.