Post Preview

Table of Contents

- Introduction to Diamond Wire Cutting

- Environmental Benefits of Diamond Wire Cutting

- Energy Efficiency and Reduced Emissions

- Precision and Structural Integrity

- Safety Enhancements

- Applications in Sustainable Demolition

- Conclusion

Key Takeaways

- Diamond wire cutting offers a sustainable alternative to traditional demolition, delivering precision, reduced pollution, and enhanced safety.

- This technique conserves resources, supports recycling, and is ideal for projects with strict environmental demands.

Introduction to Diamond Wire Cutting

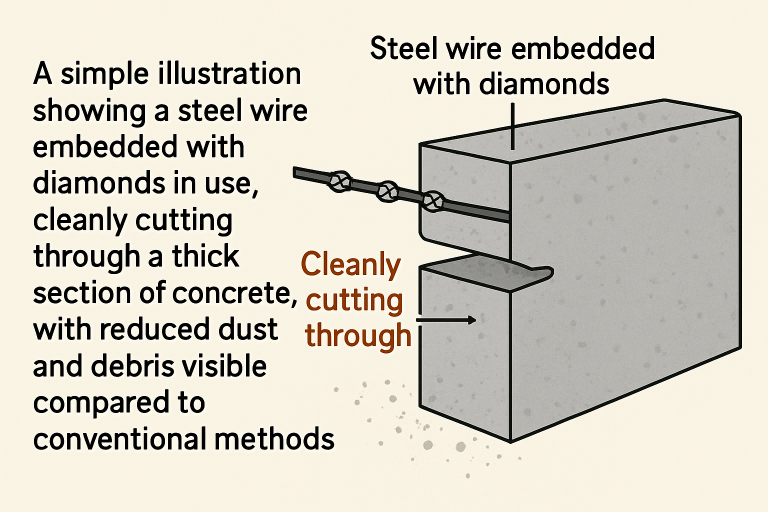

Diamond wire cutting is an eco-friendly and precise demolition method that utilizes a steel wire with industrial diamond particles to cut through tough materials, such as concrete, steel, and stone. Unlike traditional techniques that create excessive waste, it offers controlled, targeted removal without damaging nearby structures, making it ideal for complex projects and appealing to companies focused on sustainability. Building a strong partnership with providers like Bluegrass Bit is crucial, as their depth of expertise and access to advanced equipment can help maximize the technique’s many benefits and ensure that all outcomes align with modern sustainability and safety standards.

Environmental Benefits of Diamond Wire Cutting

Diamond wire cutting offers a cleaner and quieter alternative to traditional demolition methods, significantly reducing dust, debris, and vibrations that can harm air quality and disturb surrounding communities. Unlike explosive demolition or heavy mechanical breaking, it minimizes environmental disruption, making it suitable for sensitive areas like hospitals, schools, and residential neighborhoods. Its precision enables selective demolition, allowing contractors to preserve and reclaim valuable materials such as steel rebar and intact concrete. This approach not only prevents unnecessary waste but also reduces landfill usage and the need for new raw materials, thereby promoting long-term resource conservation and sustainability. According to Project Leaders Magazine, the diamond‑embedded wire technology achieves these results by slicing through hard materials with minimal force, reduced noise, and tighter cutting tolerances than traditional methods.

Energy Efficiency and Reduced Emissions

Compared to conventional demolition techniques that rely on heavy fuel-powered machinery, diamond wire cutting consumes far less energy due to its efficient abrasive action, which produces minimal heat and resistance. This lower energy demand translates to fewer greenhouse gas emissions, aligning with modern green building standards. Water plays a crucial role in the process by cooling the wire, suppressing dust, and maintaining a clean site, which helps contractors meet strict safety and environmental regulations. With its combination of low energy use, reduced emissions, and minimal waste generation, diamond wire cutting stands out as one of the most sustainable and eco-friendly demolition solutions available.

Precision and Structural Integrity

Diamond wire cutting delivers exceptional accuracy, making it ideal for projects involving partial demolition or renovations of high-value and historic structures. Its targeted approach allows only the intended sections to be removed while safeguarding adjacent areas, which is crucial for architects and engineers working on adaptive reuse or heritage restoration. This precision prevents damage to vital structural elements, such as load-bearing beams and decorative facades, thereby maintaining both safety and cultural significance. Unlike traditional demolition, the method’s gentle technique preserves structural integrity and reduces the risk of destabilizing the remaining building components.

Safety Enhancements

This method significantly improves demolition safety by allowing remote operation, keeping workers away from unstable or hazardous structures. Automated systems further reduce the risk of injury, making them ideal for projects involving unsafe buildings, high elevations, or underwater elements. According to USA Wire, diamond wire cutting also minimizes vibration and noise, preventing damage to nearby infrastructure and maintaining stability in surrounding buildings. It’s quiet, low-impact operation benefits sensitive environments, such as hospitals, laboratories, and offices, allowing normal operations to continue while ensuring the safety of both workers and the community.

read more : The Rise of Burmese Curly Wig

Applications in Sustainable Demolition

Diamond wire cutting is widely used for dismantling heavy concrete bridges, cutting underwater piles, and removing thick industrial or reactor structures. Its adaptability allows for clean material separation in urban settings and environmentally sensitive areas. The method is preferred by municipalities, developers, and infrastructure agencies for its ability to limit dust, vibration, and ecological disruption. By supporting recycling efforts and meeting strict environmental regulations, diamond wire cutting offers a sustainable solution for both large-scale infrastructure projects and smaller, specialized demolitions.

Conclusion

Diamond wire cutting combines precision, safety, and sustainability, making it a forward-thinking choice for modern demolition needs. It’s a low-impact approach that protects communities and the environment while achieving exceptional results. Partnering with experienced providers ensures optimal performance and compliance with project goals, positioning the method as a leading solution for sustainable deconstruction in the evolving construction industry.