Automation in the industrial sectors is a very rapidly-moving process and the Solid State Relays (SSRs) is one of the factors that is changing fast. These are the kind of electronic appliances which are applied instead of the mechanical relays which guarantee much better reliability, speed, and performance. This has necessitated solid state relays being a very important component in the new day automation system because it eliminates electrical time wasting since there was the need to rearrange moving elements of the old fashion relay which makes it efficient and reduces downtimes. The article discusses the presence, operation, and the explanation as to why solid state relays are reshaping the industrial automation world especially due to the nature of reliability and quality being portrayed by the mature solid state relay enterprises such as OMCH.

A Solid State Relay?

Electronic switching device to switch power to an electrical load using no moving parts; used in control systems and in interface applications where higher reliability is required compared to mechanical switch. Unlike conventional electromechanical relays where a circuit is closed or opened with aid of a physical contact material SSRs substitute the contact material with semiconductive material to achieve the same effect. This mode of performance is quicker switching, more sustainable, and unable to work under harsher conditions. The SSRs too contain no component of a moving part and as a result there is minimal wear and tear hence few maintenance thus increasing the life of the relay. Control of electrical circuits is the key which makes industrial automation the area where SSRs are particularly convenient to use. When choosing SSRs, industries turn to well-established solid state relay manufacturers like OMCH for their superior build quality and performance.

Significant advantages of Solid State Relays in Industrial Automation Architecture

The advantages of solid state relays are numerous and hence in absence of them, industrial automation will be out of the question. First of all, SSRs have no moving parts which leads to the soaring rise in durability. Traditional electromechanical relay is likely to become worn out after the period of time as this is the same mechanism which is utilized to actuate it and thus becomes worn out leading to wastage of time in this case as well. Relative to this, the SSRs operate with significantly fewer life times since they are unlikely to be mechanically destroyed. Besides, SSRs require lesser switching time compared to that of the mechanical relays. This rapid response is vital in rapid response production systems such as the robot arm, conveyor belt or the automatic assembly line. They also happen to be very quiet in their operation that is why they are the better option to be installed in a location where noise needs to be non-existent as in the case of the clean room or in the noise-sensitive industries. The other greatest feature is that it is able to withstand harsh environmental conditions like high temperatures, vibrations or dust among just a few industrial surroundings. Integration of solid state relay manufactures like OMCH ensures that such rough environments give the most optimum results in regards to performance and reliability when used.

Industrial Automation use of Solid State Relays

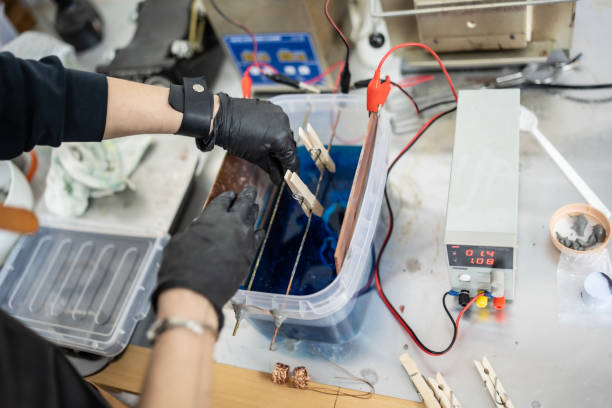

Solid state relays are used in automation systems of industrial systems where the controlled object is electrical power flow to other objects i.e. motors, lights, heating elements, etc. The SSRs which include the input control signal usually start in the form of a microcontroller or any other automatic system. Once the SSR is given the control signal, it relies on the use of semiconductor devices like the use of triacs or thyristors, in order to enable or deny the possibility of an electrical current entering into the load. The electronic device involved in the switching is the electronic components of the relay and it operates the device to switch on or off without the presence of any mechanical movement. And this is so that it must have very precise control in place and reduce wear and tear that is present as far as the mechanical relays are concerned. Because SSRs have many times faster switch-rate, (as compared to mechanical relays) they are required in high speed applications, where they need to respond fast. OMCH has offered SSRs and these can withstand high load and are so durable that this is the best combination to match numerous industrial applications.

Application of Solid State Relay in industrial automation

The versatility of the solid state relays has been very instrumental in industrial automation in various sectors. Indicatively, SSRs play an important role in motor control because it requires a stable and fast switch to control electric motors. Robots, and other devices The ability of an automated conveyor to perform at the maximum level is enhanced by the SSRs which aid on the speed and reliability of the device. There are too many applications in heating control such as the use in industrial ovens or heating elements. The high rate of reaction of the SSRs enables a determination of a specific control of temperature that is necessary in food processing or production of materials. Also, SSRs are very useful in the lighting control system of large production facilities and factories, in which the safety may be enhanced also by the utilization of automated lighting systems, used to reduce the consumed gas share, as well. The other applications where SSRs excel include overcurrent protection where SSRs are employed as a second barrier to an equipment being damaged due to over currents which may be conducted through an electrical system. The solid state relays (ssr) in more advanced automation systems offered by the solid state relays (used in robotics and automation), offer a higher level of control of power to the motors, actuation and sensors. The SSRs varied application in this flexible application makes them worth a great deal in industrial automation efficiency and OMCH has the solutions to most of the industrial needs.

read more : Best Cat Trees for Large Cats – Stable and Durable Choices

Conclusion

In conclusiveness, the solid state relays (SSRs) have incorporated modernized industry automation which has numerous advantages as opposed to the traditional, mechanical type of relay. They are swift, life long, electromechanical and do not require moving parts in high precision switching and high reliability applications. SSRs are creating a revolution in industrial processes and enabling a higher efficiency, whether in motor control, heating systems and in robotics. When purchasing a solid state relay by a well-rated producer like OMCH, you are assured that you will acquire a high quality product, which will be reliable, as well as have the capacity to satisfy the needs of an industrial setting. Industries can streamline their operation, achieve low maintenance rate and become more productive with use of solid state relays. The solid state relays will only be more significant in the direction that operating the industrial activities will take with the further development of automation.