The B2B business industry requires high-performance parts to be accurate, durable, and efficient. Investment precision casting manufacturers provide a complex and high quality part creation solution with great production optimization. Bessercast and similar companies have perfected these methods to provide high precision, industrial grade components for the aerospace, automotive, energy, and varying other techniques. This work examines the benefits of investment casting manufacturers in precision parts for B2B companies in material performance, cost value, operational synergy, and overall value over time.

Knowing Precision Investment Casting

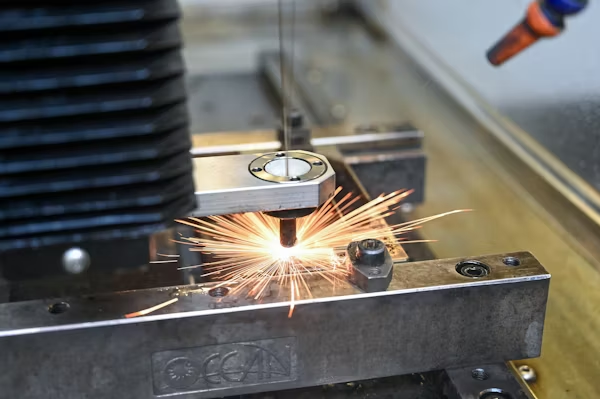

Investment precision casting, or lost wax casting, is a manufacturing process that enables the precise creation of complex metal parts with very tight tolerances and superior finish. This process starts with the production of wax patterns, for which then a refractory material mold is made. The refractory helps in the formation of the empty chamber, which is then filled with molten metal, for high consistency and accuracy parts.Among B2B enterprises the importance B2B enterprises the importance of the precision investment casting manufacturers is great for the application in which machining and conventional forging cannot achieve required efficiency of complexity. Automated workflows and precision investment casting manufacturers eliminate the secondary processes needed for dulling without lessening the precision of the dimensions. Companies such as Bessercast apply advanced casting vacuum and investment casting using silica sol to produce components for critical fields like aerospace, automotive, and energy.

Some of the most economically efficient metallurgical properties of this manufacturing methodology are waste reduction and production on near-net shape. Supported by high-quality, repeatable parts, precision investment casting manufacturers B2B enterprises to streamline supply chains, cut redundancy in assembly, and increase final product reliability.

Manufacturer Versatility and Sophisticated Alloys

The simplest and most rapid means of forming industrial grade investment castings with the precision investment manufactured custom castings as outlined in the accompanying document. The accompanying document outlines custom castings which are outlined in detail. The documentation detail outlines custom castings.

The selection of these materials focuses on their optimal thermal, mechanical, and chemical characteristics. For example, aerospace components, such as turbine blades, need nickel-based alloys to survive elevated temperatures and still retain mechanical strength. In the same manner, aluminium and stainless steel alloys used for turbocharger housings in automotive and aerospace provide strength and resist corrosion while being lightweight.

Manufacturers of precision investment casting utilize sophisticated simulations, mold design, and thorough quality checks to allocate each material to different components based on specific characteristics. For example, bessercast uses sophisticated casting simulation paired with expert metallurgical examination to achieve microstructure uniformity and eliminate dimensional and form defects. The combination of meticulous engineering and material knowledge with adept production makes it easier for B2B companies to provide components that fulfill industry demands as well as their client’s needs.

Cost Efficiency and Operational Benefits

B2B companies enjoy working with precision investment casting manufacturers because of the clear economical and operational benefits. For example, traditional methods of making components, such as CNC machining or forging, have several stages of production, where material wastage or excessive finishing processes are common. In comparison, investment casting brings manufactured components that are very close to the desired shape, needing very few operations afterwards.

Fewer manufacturing steps means less labor, material, and time needed to complete each cycle. In addition, precise investment casting companies are able to scale the production to accommodate bulks without any tradeoffs, and deepens their competitive edge. Clients like Bessercast make use of automated shell making lines integrated with quality control systems to optimize workflow, reduce lead time, and make sure B2B projects are delivered on time.

On top of that, the capability to cast multiple geometries at the same time in one mold eliminates several assemblies needed for the end product. In automotive, this means lighter and more efficient engine components, and in aerospace it minimizes the number of parts, easing maintenance and enhancing system support. Precision investment casting companies also offer their B2B clients economical production without slashing quality standards.

Design Convenience and Personalization

The investment castings held the specific advantages of ease of design and the ability to manufacture a wide array of geometrically complex components. B2B clients are able to make use of tools such as ultra-thin walls, undercuts, and intricate detailing.

Customization options such as unique surface textures, metallic coatings, and embedded logos can provide extra value for B2B clients seeking to set their offerings apart from the competition. Vacuum casting and silica sol molds, for example, enable the attainment of complex geometries and still maintain the fundamental qualities of accuracy and tensile strength.

Using such Design Obligation Benefits, precision investment casting manufacturers assign B2B clients reduced prototyping time, simplified assembly, and enhancement of functional capabilities. Suppliers to the aerospace, automotive, and energy sectors have all praised our ability to take complex designs and offer disassembled products, where each component is precise, dependable, and ready to use. This ability showcases the power of investment casting as a manufacturing solution for heavy-duty applications.

Quality Assurance and Long-Term Reliability

Within the context of component manufacturing for high performance applications, the importance of precision and reliability is often overlooked. Because of the complex nature of the industry, precision investment casting manufacturers deploy a system of documented procedures to manage the production process and ensure internal and external quality is delivered optimally. Steps such as external audits alongside internal checks of Product Assurance Assurance, Archival of Documents, Reliability, and Design Quality all aim to ensure mechanical and structural integration, followed by dimensional control, metallurgical breakdowns, and mutilation assessments.

Components are sure to have uniform material properties, tight tolerances, and excellent surface finish when working with reputable precision investment casting manufacturers. Companies like Bessercast also provide other integrated services like heat treatment, CNC machining, surface finishing, and assembly, offering a solution that simplifies the supply chain and improves product reliability.

For B2B companies, the combination of quality assurance and long-term reliability means fewer component failures, lower maintenance costs, and overall enhanced performance. These benefits are particularly valuable in the aerospace and automotive industries, where safety and compliance to regulations are critical, along with product durability.

Conclusion

Investment casting suppliers have precision B2B advantages for the production of high-performance components. B2B manufacturers are able to solve complex requirements in aerospace and automotive industries, along with other industries, with investment casting’s material versatility, cost-effective high-volume production, design flexibility, and quality assurance.

Collaborating with precision investment casting manufacturers simplifies production, minimizes waste, refines supply chains, and sustains a competitive edge. Sophisticated methods, electronic oversight, and environmentally conscious methods continue to add value to precision investment casting business to business B2B clients and casting clients. Partners offering optimal business performance, investment scalability, and precision geared investment casting technology manufacturers are calculated business investments to guarantee long-term growth and industrial advancement.

also read: Steps to Download MetaTrader 5 Safely Without Errors