In industrial automation and manufacturing, compressed air systems are a vital component of an operation. These systems provide the backbone for powering actuators, valves, and even driving pneumatic tools and robotic arms. However, the reliability and longevity of compressed air systems heavily depend on the system’s air filter components. Airborne particulates such as dust, oil, and moisture have the potential to hinder performance, create equipment failures, and inflate energy costs. For operational stability and system longevity, B2B companies treating compressed air systems are concerned about the performance needs to provide.

To assist industrial clients from various industries, https://www.omchele.com/ru/frl-units/ Omchele offers reliable and effective air filtration systems and FRL units that are specifically designed to provide maximum integration value to pneumatic systems while minimizing system downtime.

The Function of Air Filters in Pneumatic Systems

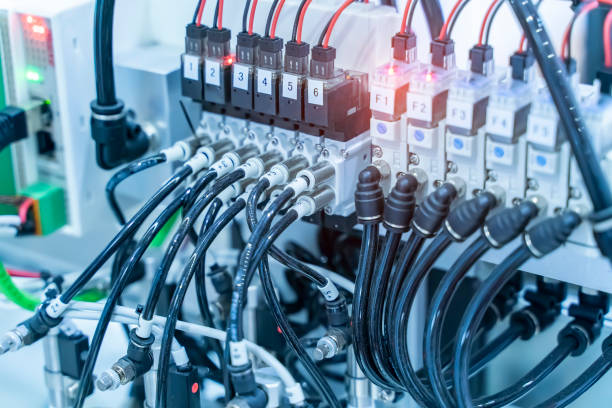

Air filters are an essential component of the FRL units—Filter, Regulator, and Lubricator—that keeps the compressed air clean, well pressurized, and has the accurate lubricants in them. Each of these components has its responsibilities, and the air filter, as its name indicates, defends pneumatic components and systems from incoming particulates.

In compressed air systems, the contaminants include air:

- Solid particles: Dust, rust, and metal shavings from pipelines

- Oil mist: Released from compressors and other machinery

- Moisture: Caused by condensation from the compressed and cooled air

These contaminants can cause damage to valves, clog orifices, and cause actuators to work poorly. Good air filters remove these contaminants from the air stream, which protects critical system surfaces. Consistent equipment operation and extended equipment use result from good air filters.

Mechanical air filters usually work by mechanical separation where particles are captured and held in the filter. Smaller particles such as oil aerosols are stuck together in a process known as coalescing filtration and are removed.

READ MORE : Why Proper Storage is Essential for Antique and Modern Firearms

Types of Industrial Air Filters and Their Applications

Based on the system requirements and the types of contaminants, the different types of air filters can be used. System designers and facility managers in B2B should select the filters based on the air quality and precision requirements of the facility.

Particulate Filters

Particulate filters capture solid particulates using porous filter elements like sintered bronze or fiber. These filters are particularly indispensable in manufacturing industries where heavy dust or metal debris is prevalent. Typical applications include:

- Metalworking Shops

- CNC Machining Centers

- Paint Spraying Systems

Coalescing Filters

Oil aerosols and sub-micron particles require coalescing filters designed specifically for these sub-micron particles and aerosols. They are often employed in areas requiring ultra-clean air. These filters are utilized in:

- Pharmaceutical Manufacturing

- Food and Beverage Processing

- Medical Device Assembly

Activated Carbon Filters

Elimination of odors and vapor-phase contaminants is easily carried out through the use of Activated carbon filters. They are usually employed together with coalescing filters for complete air purification. These include:

- Electronics Manufacturing

- Cleanrooms

- Laboratories

All of these filter types can be fitted into modular FRL units for more compact and efficient system design.

Importance of Air Filtration In B2B Businesses

Automated industrial processes rely heavily on the air filtration systems in use. Any failure in components may result in equipment damage, production downtime, or the production of contaminated products. In industrial settings, proper air filtration can significantly lower these risks:

Reduced Maintenance Costs

Filtration systems that do not work effectively increase the contaminants in air. This increases the abrasives and wear on the air compressor systems and increases the necessary maintenance procedures. Correct filtration alleviates the need to clean, replace components, or repair systems on the fly.

Improved Energy Efficiency

Air contamination can severely lower the efficiency of every pneumatically powered device. This inefficiency increases the overall power consumption of the device and the energy consumption of the B2B company. In contrast, clean air alleviates components to operate at peak efficiency decreasing energy consumption.

Higher Product Quality

For the pharmaceutical and food processing industries, sterile environments are critical. B2B companies serving these industries require air filtration to maintain compliance with the stringent quality marking.

Longer Equipment Life

Contaminated air promotes the wearing down of valves, cylinders, and pneumatic systems. Consequently, every single machinery or pneumatic device powered through air systems becomes more durable and their systems more expensive to maintain.

B2B companies looking for reduced business downtime and lower maintenance investments need filtration systems. Tested and proven FRL units specialized for industry filtration needs are specially tailored to provide B2B companies value through investing in reliable filtration solutions.

Deciding Factors When Choosing an Air Filter

It is not particularly straightforward picking an air filter. For B2B purchases and technical teams, compatibility and longevity creates an intricate web of variables.

Air Flow and Pressure Requirements

To function properly, filters must be matched to the system’s pressure and flow requirements. Filters have their own distinct systems. Too much filter and not enough system creates poor flow.

Level of Filtration

Micron ratings define the size and number of particles a filter is able to capture. The most common levels of filtration range from 5 microns to 0.01 microns. The level of filtration required is based on the sensitivity of the application used.

Installation and Port Size

The filter’s port size needs to be matched to your piping and valve assemblies to not hinder integration. In addition, look for modular filters that can be combined with regulators and lubricators for space conserving arrangements.

Other Operating Parameters

For systems working in a corrosive environment with high temperature, filters made with corrosion resistant materials, temperature resistant seals, and heat resistant materials are to be used.

Filter Change Frequency

The ideal filters are the ones that are easy to check, clean, and replace. The presence of the transparent bowls and automatic drains, along with visual indicators means maintenance becomes easier, reducing downtime.

Omchele as an example provides solutions that meet operational and industrial standards for users as industrial FRL units and filters.

Innovations and Trends in Industrial Air Filtration

Innovation in smart manufacturing and energy-efficient systems technologies have also advanced the development of pneumatic technologies. Innovations in air filtration systems and devices have also increased in the area of materials, design, and monitoring systems.

Modular FRL Units

In contrast to the traditional design which used separate filter, regulator, and lubricator components, many industries have started to adopt modular FRL assembly units. Such form of separate modular units provide the following benefits:

- Compact design

- Simplified installation

- Lower pressure drop

- Easy maintenance and part replacement

These separate modular units are extremely beneficial in OEM equipment or confined spaces.

Intelligent Filter Monitoring

The advancement of filters and sensors in modern air compressors through the integration of IoT systems and sensors have given rise to smart filters. Smart air filters have the capability to do the following:

- Alert users to pressure drops

- Predict maintenance needs

- Log filter performance for further analysis

Future filters are in the process of being developed to reduce unscheduled maintenance and enhance asset management, thereby improving uptime and resource optimization.

Eco-Friendly Materials

Development of filters made from recyclable or biodegradable materials is on the rise, particularly in industries focused on sustainability targets. New filter media is also being developed for greater durability and longer life spans.

Ultra-Low Energy Consumption

Ultra-fine filtration is achievable with new designs that create lower pressure drops. This results in reduced energy use while preserving system cleanliness. These filters assist industries in achieving both environmental and financial objectives.

Conclusion

Within a compressed air system, air filters are frequently neglected, but they are critical for protecting machinery, preserving quality, and minimizing costs. For B2B industries like manufacturing, food processing, pharmaceuticals, and automation, air filtration goes beyond being a prudent investment—it is vital for operational efficiency and long-term sustainability.

With greater system sophistication in industrial applications, the need for robust, versatile, and high-performance filters is more pronounced. Omchele meets this need with a wide selection of FRL units and air filters tailored to the stringent quality, regulatory, and integration expectations of modern B2B industries.

If you are creating a new pneumatic system or improving an existing one, prioritizing air filtration will provide greater efficiency, reduced upkeep, and enhanced operational performance.