Key Takeaways

- Rotary gear pumps are integral to multiple industries due to their robust handling of diverse fluids and applications.

- Technological advancements have improved their adaptability and enhanced operational efficiency.

- A broad understanding of these pumps’ use cases supports more strategic and cost-effective industrial operations.

Table of Contents

- Oil and Gas Industry

- Chemical Processing

- Pharmaceuticals

- Food and Beverage

- Agriculture

- Paints and Dyes

- Cosmetics Industry

- Textile Industry

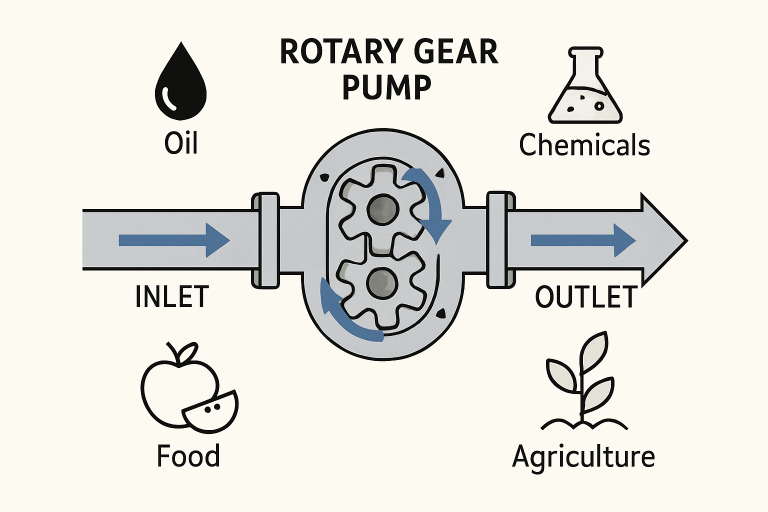

Rotary gear pumps are essential equipment in fluid transfer systems, widely respected for their reliability and versatility. As industrial processes become increasingly advanced and specialized, the demand for innovative and efficient pump technologies continues to grow. Modern advancements have enabled rotary gear pumps to play crucial roles in various sectors that require precision, durability, and hygiene. For professionals seeking the right solutions to optimize their operations, a comprehensive overview of these pumps and their dynamic uses is invaluable. Further insights into the technology and its industrial impact are available at Cbeuptime.com, which explores the latest pump systems and their real-world applications.

Whether handling harsh chemicals or maintaining the quality of consumables, rotary gear pumps meet a spectrum of industrial demands. Their adaptability and performance improvements, thanks to innovations in materials and engineering, ensure they remain relevant and reliable, even as standards and regulations become increasingly stringent across various markets. A thorough understanding of the benefits and recent innovations in rotary gear pumps enables businesses to make informed, efficient decisions about equipment choices for both new installations and upgrades.

Oil and Gas Industry

Rotary gear pumps play a critical role in the oil and gas industry, where they handle the transfer and processing of crude oil, refined fuels, and high-viscosity lubricants. Their robust construction allows them to withstand the high pressures and temperatures often encountered in upstream and downstream operations. By offering smooth, pulsation-free flow, these pumps ensure the stability of pipelines and production systems, reducing maintenance intervals and unscheduled downtime. Leading energy companies continue to invest in rotary gear pump technologies for their reliability in demanding environments, as discussed in recent features from the U.S. Department of Energy.

Chemical Processing

Chemical manufacturing plants require pumping solutions that can handle corrosive and hazardous substances with precision and safety. Rotary gear pumps facilitate the transfer of acids, additives, polymers, and solvents, maintaining consistent flow rates even in the presence of fluctuating viscosities or challenging temperatures. Thanks to recent innovations in material sciences—such as advanced coatings and corrosion-resistant alloys—these pumps provide the high-performance and safety levels integral to modern chemical production. Additionally, new seal and bearing technologies have further minimized leakage risks and extended pump service life.

Pharmaceuticals

The pharmaceutical sector relies on stringent hygiene and contamination controls during manufacturing and the transfer of solutions, such as syrups, complex suspensions, and injectable products. Rotary gear pumps designed for this sector are constructed from hygienic materials, featuring easy-to-clean surfaces and design elements that facilitate sanitary procedures. Their ability to deliver accurate and repeatable dosing helps ensure the quality and safety of finished products. As regulatory demands continue to rise, manufacturers are turning to rotary gear systems that exceed standards for product purity and process integrity, with further reading available on Pharmaceutical Technology.

Food and Beverage

When it comes to edible oils, syrups, dairy products, and other viscous consumables, rotary gear pumps excel at ensuring hygienic and contamination-free processing. Gentle, low-shear handling maintains the consistency, taste, and texture of foods while complying with food safety regulations. Modern pump designs incorporate stainless-steel contact surfaces and aseptic seals, enabling processors to meet the exacting requirements of health authorities. These features have proven essential for global food brands seeking both quality assurance and production efficiency.

Agriculture

Agricultural operations demand versatility and ruggedness from their pumping solutions. Rotary gear pumps enable precise dosing and transfer of pesticides, fertilizers, and irrigation fluids. Their ability to manage everything from thin liquids to thick slurries makes them valuable in both crop cultivation and livestock farming. Enhanced by energy-efficient drives and smart controls, these pumps are helping farmers achieve greater consistency and sustainability in their operations, as highlighted in research on Successful Farming.

Paints and Dyes

Manufacturers of paints, dyes, and coatings rely on rotary gear pumps for the precise movement of viscous, pigmented liquids, ensuring smooth, even processing. These pumps are engineered for tight tolerances and low-shear operation, preventing contamination and maintaining color uniformity. Advanced models also provide easy disassembly for cleaning, allowing for efficient switching between color batches, a crucial step in minimizing waste and ensuring quality in high-volume production lines.

Cosmetics Industry

Cosmetic manufacturers face challenges in processing and packaging viscous creams, lotions, and gels. Rotary gear pumps are favored for their ability to handle these challenging fluids while maintaining absolute product purity and batch-to-batch consistency. Hygienic construction and CIP (clean-in-place) capabilities reduce downtime and support stringent quality controls within the cosmetics sector, helping brands protect their reputations and meet safety regulations.

Textile Industry

Within innovative manufacturing, rotary gear pumps are utilized to transport dyes, sizing agents, and finishing chemicals, ensuring even application and reproducible results across large batches. Their robust and reliable operation helps drive the efficiency of dyeing, coating, and fabric treatment processes—critical factors in meeting modern textile production quotas and standards.

For those seeking an in-depth look into typical rotary gear pump configurations and modern solutions for fluid handling in industrial settings, refer to this authoritative guide from Machine Design.

With ongoing innovations—such as wear-resistant coatings and automated performance monitoring—rotary gear pumps are poised to deliver even greater value across new and established industries. Whether in resource extraction, advanced manufacturing, or consumer product sectors, understanding the robust capabilities of rotary gear pumps can drive efficiency, reduce operational costs, and foster long-term process improvements.